From creating customized products to increasing efficiency, businesses are leveraging laser machines for a multitude of applications. Lasers have become increasingly popular as they offer precision and cost-effectiveness that other traditional methods cannot match.

This article looks at the success stories of companies that have taken advantage of this technology and how it has helped them achieve their goals. Through case studies from various industries such as manufacturing, automotive, medical device production, and more, the article will explain the benefits that laser machines can bring to your business.

It also provides insight into what you should consider when investing in one and how you can ensure optimal results with its use.

Automotive Manufacturer Reduces Production Time with Laser Machines

One successful example of a business leveraging the power of laser machines is an automotive manufacturer. By utilizing laser machines, they were able to reduce production time and increase efficiency in their operations.

This was accomplished by using lasers to drill through metal faster and with greater accuracy than traditional methods. The precision and speed at which the manufacturers could now work allowed them to produce higher volumes of cars much quicker than before.

Additionally, this saved them money as they no longer needed to use costly materials or pay for extra labor hours required during slower processes. As a result, the automotive manufacturer was able to improve customer satisfaction while also improving their bottom line.

Textile Company Increases Efficiency and Quality Using Laser Cutting Technology

One company that has successfully leveraged laser cutting technology to increase efficiency and quality is a textile manufacturing business. The use of laser machines has allowed the company to automate its production process, meaning it can produce higher volumes with greater precision than ever before.

This automation also reduces labor costs, allowing the company to save money while still producing high-quality products. Additionally, since laser cutters are highly precise and accurate, this increases the overall quality of the finished product as well.

As a result, customers receive superior goods at lower prices compared to those produced without lasers. Ultimately, this textile business’s decision to invest in laser cutting technology demonstrates how businesses can unlock new levels of productivity by embracing innovative tools such as these.

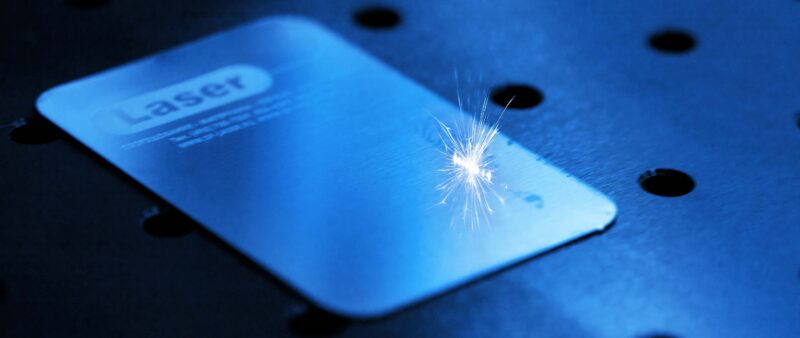

Metal Fabrication Business Achieves Greater Precision with Advanced Lasers

A leading metal fabrication business earned an impressive return on its investment in advanced laser machines recently, resulting in greater precision and efficiency in its operations. With the implementation of these cutting-edge lasers, the company was able to achieve improved accuracy and faster completion times for their projects.

The new technology also allowed them to create intricate designs with extreme detail that were not possible before. By taking advantage of this highly precise tooling, the business was able to increase customer satisfaction significantly while increasing its profits as well. As a result of implementing modern laser machines, they now have more control over their workflow than ever before – from start to finish – which has enabled them to take on even more complex projects with ease.

This case study proves that investments in innovative technologies can lead to increased productivity and dramatic improvements in overall quality for any type of business.

Aerospace Company Gains Cost Benefits from Laser Machining Solutions

An aerospace company recently experienced the benefits of laser machining solutions first-hand. The company was able to cut costs and increase production efficiency with the use of laser machines.

Through precision cutting and engraving, they were able to reduce waste materials while achieving higher accuracy in their components. Additionally, their parts were completed faster due to the speed at which a laser machine can work compared to manual labor or traditional methods.

With quicker turnaround times, this aerospace company was able to better meet customer demands and stay competitive in the industry. Businesses like this one have recognized how much time, energy, and money can be saved when they leverage laser machines for machining needs.

Electronic Device Manufacturer Improves Product Reliability with Laser Welding Processes

A case study showcasing the success of a leading electronic device manufacturer reveals how laser welding processes have helped the company improve its product reliability. By utilizing the precision and accuracy of lasers, they can create stronger welds that last longer, resulting in products with increased durability.

The process also helps them save time and money because it is faster than traditional methods; less material is wasted due to its pinpoint accuracy as well. Additionally, customers appreciate that they can trust the quality of each product knowing that it has been constructed using advanced laser technology.

This successful example proves how powerful laser machines can be when applied correctly for maximum efficiency and effectiveness.

Conclusion

This case study has demonstrated the success that businesses can achieve when they leverage laser machines. Laser machines provide a powerful and efficient way to increase productivity while reducing costs and improving accuracy in their processes.

With the right implementation, laser technology can be a major asset for any business looking to stay ahead of the competition and maximize profits. Whether it is cutting material or engraving intricate designs, these tools are essential for taking your business operations to the next level.